Large eCommerce sites like Amazon have taken over the retail space. For a smaller online retailer shipping is one hurdle to the perfect deal, but large eCommerce sites have unwittingly given smaller retailers plenty of lessons on how to ship effectively. We’ve collected five of those lessons.

1. Additional Warehouses Means Nearby Shipping

Nearby warehouses means reduced shipping costs. Large eCommerce companies can keep shipping costs low because they can offer strategic shipping routes. Shipping from a warehouse closest to the client can keep your overhead low, and you can then pass on those saving to consumers. You can also market to customers who live nearby your warehouses with offers and shipping savings.

2. Reduce Cost by Increasing Average Order Value (AOV)

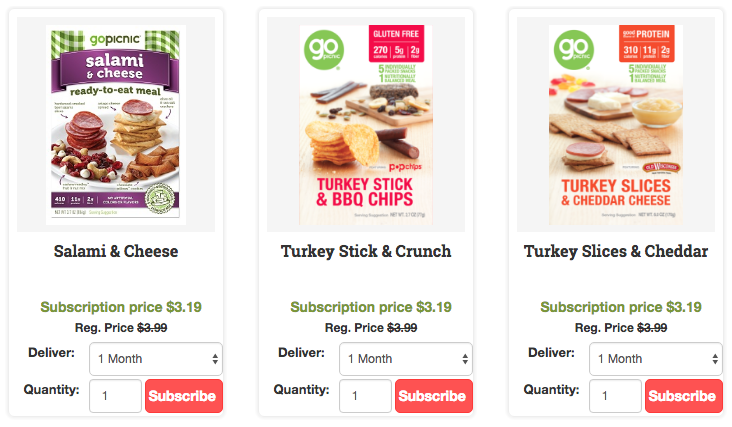

The idea is to encourage shoppers to increase AOV relative to shipping costs. Incentivizing products through merchandising, special offers, shipping policies or subscriptions will reduce the overall shipping costs and is a great way to keep your shipping costs down. Offering bulk products, or incentivizing clients to buy more with reduced shipping costs could help you reduce your overhead costs.

Quantity pricing typically represents that larger quantities means reduced shipping costs per unit purchased.

Subscription model allows you to ship whenever (day and time) is the cheapest.

3. Zone Skipping

Trucking your shipments is another form of strategic shipping. You can bulk shipments together and truck them to a centralized location. The shipments can then be handed off to a carrier to finish the delivery door to door.. This can save you immensely on freight costs if you do have sufficient daily package volume.

4. Negotiate a Better Inbound Rate

Higher shipping volumes yield more discounts. To bulk up your inbound volume ask your suppliers to use your account number for inbound shipments. This can help you when you negotiate inbound and outbound rates with a carrier such as UPS, FedEx or DHL. A better shipping rate can translate into huge savings over time.

5. Internal Warehouse Organization

Time is money, and when it comes to shipping that can translate into big money. Organize your internal picking to better utilize your team of workers. Try out zone picking (instead of standard order picking, or wave picking) within your warehouse to help your employees get orders ready for shipping more efficiently. This is also the first step to more strategic shipping procedures.